Adopting a Lean Coating Process

September 23, 2020

Why Now is the Right Time to Switch to Fully Formulated Film Coatings

Pressure on manufacturing has been building to switch to fully formulated film coatings even before the pandemic struck. Now, with heightened concerns about inherent risks in supply chains, the benefits of new, leaner production models and minimizing risk to supply chains has become an overriding priority.

Colorcon is at the forefront of this movement to leaner manufacturing, making it easy for companies to convert to a simple fully formulated film coating system. With seven manufacturing locations, strategically located around the globe, Colorcon provides an uninterrupted supply of our full portfolio of innovative solutions based on Opadry® Complete Film Coating System.

Opadry Film Coatings vs. the Do-It-Yourself (DIY) Approach

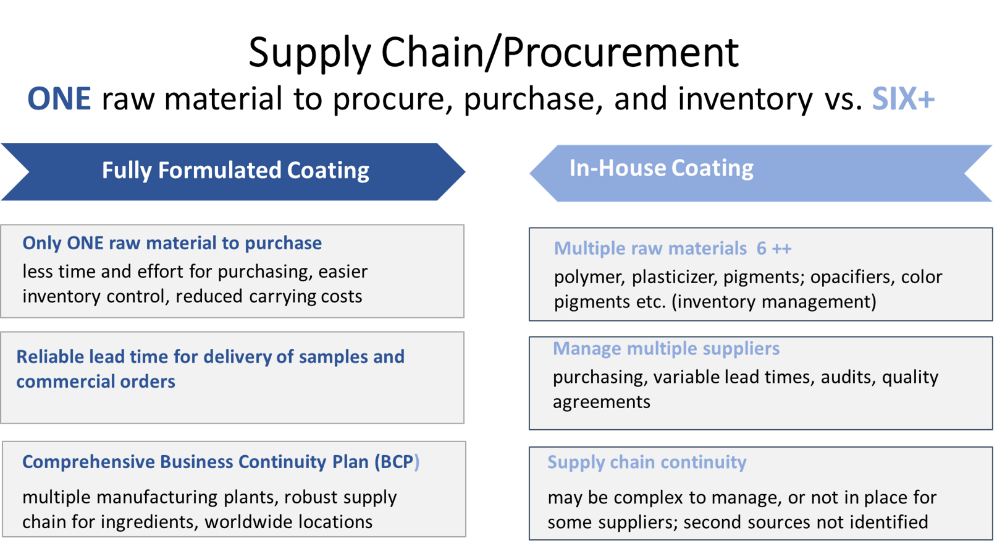

Fully formulated coating systems provide substantial benefits over in-house systems such as: reduced inventory management, better coating efficiency, increased manufacturing capacity, batch-to-batch consistency and reduced overall cost.

In-house coating formulations, on the other hand, require multiple steps. Raw materials must be sourced, quality control procedures must be completed, vendors need to be audited and approved. There’s also a greater risk of error due to the mixing of several ingredients and pigments and the addition of each material adds time and effort.

With Colorcon there is only one raw material to procure, purchase and maintain inventory for versus the six or more materials necessary for the in-house approach.

Adopting a Lean Coating Process

Colorcon is renowned for its customized, one-step film coating systems which combine the main ingredients – polymer, plasticizer and pigment – into a dry concentrated form. The range of Opadry fully formulated film coatings provides best-in-class performance, ensuring quality and consistency for a range of functional applications and color requirements.

Uniform color is one of the most difficult attributes to consistently achieve with multi-step in-house coatings. Ingredients need to be milled, mixed, blended and even then, still often result in inconsistent batches and quality failures leading to rework or rejection.

Colorcon’s instrumented visual color difference testing ensures consistent color, every single time. Specification tests confirm the hydrated powder matches the individual formula standard and color is measured using a reflectance spectrophotometer.

Rigorous formulation development, material and supply chain controls, plus operational processes and testing requirements within a certified quality management system are key to exceptional and most importantly, repeatable, coating performance.

Quality by Design to Ensure Reproducibility

Colorcon has adopted four quality by design (QbD) elements as principles to ensure coating formulations are robust and innovative.

- Design of experiment (DoE) during development to ensure formulation and coating process optimization.

- Process validation ensures every new Opadry system meets required quality specifications at all Colorcon locations.

- Stability testing according to ICH guidelines ensures consistent and stable product appearance, color, dispersion properties and coating performance during the specified shelf-life of the product.

- Master formulation serves as a global reference to create all subsequent batch records, no matter where it’s produced.

A fully formulated Opadry system addresses raw materials, appearance, color variation, stability and batch-to-batch consistency. Our Area Technical Managers are on hand to help customers with understanding the critical process parameters (CPPs) for their equipment, such as dispersion spray rate, spray distribution, process temperatures, airflow, coating solids concentration, pan loading and pan speed.

Worldwide Support - 24/7

Suppliers with a robust business continuity planning (BCP) process help to minimize risk. With over 50 years of service, Colorcon not only upholds an unparalleled pedigree of developing innovative coating solutions but also provides extensive technical knowledge to ensure coating equipment and processes are optimized.

With 22 technical support laboratories around the world, Colorcon gives our customers the best starting point for the optimal coating process. Within our labs, you can run trials, seek advice, and get insights on troubleshooting problems. There are online tools available to support your development, including the online Color Selector to visualize color and logo options. You also have the option to join the Colorcon Coating School which addresses theoretical aspects of film coating, accesses hands-on experience where allowed, and showcases production-scale coating equipment to gain insight into the latest developments.