Now that we’ve established that food color matters – a lot – I’d say it’s even worthy of a quote!

“When you entice the eyes, the stomach and revenue follow.” – the team at Colorcon Specialty Markets, just now.

The term “food dye” is often used as a catch-all term for all food colors, regardless of the application, but there are substantial differences between lake pigments and dyes – both of which must be registered with the FDA for use in food. Another thing to note is that D&C colors can only be used in drugs and cosmetics; FD&C colors are able to be used in foods, drugs, and cosmetics.

What Are Lake Pigments and Dyes, and How Are They Different?

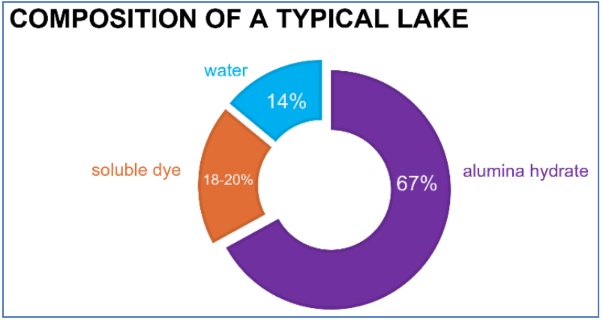

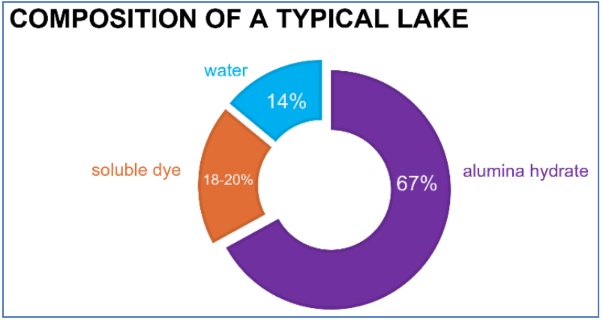

In food applications, all colorants are considered food additives. Both lake pigments and dyes fall under the category of “synthetic pigments.” Dyes are essentially a pure colorant with decent light and heat stability, while lake pigments are comprised of alumina hydrate, dye, and water, offering better stability.

stability.

Lakes are dispersible and can be mixed with a variety of carriers like oils, glycerin, propylene glycol or sucrose syrup. Dyes, on the other hand, are water soluble and won’t mix well with oils or fats. Lakes can also be used in applications where there isn’t enough moisture to dissolve dyes.

While both play an important role in food coloring, choosing between a lake pigment or a dye often comes down to the specific application, your ingredients, the desired texture or color, and other finished product characteristics.

4 Key Differences Between Lakes and Dyes

Here’s a rundown of four of the key characteristics and performance differences between lakes and dyes to help you better understand the issue.

Opacity

Lake pigments tend to be somewhat opaque while dyes are transparent. Opaqueness offers key advantages for certain applications. It provides better reflection on the surface of the coating, an ability to mask core defects, a perception that color is independent of the thickness of the coating, and the ability to deliver a more uniform appearance at lower weight gains.

ability to deliver a more uniform appearance at lower weight gains.

Dyes often offer the opposite, with the perception of color and uniform thickness more dependent on coating thickness. Thicker coatings, which are also necessary to reduce the appearance of defects, typically involve more weight gain for the product.

Migration

Color migration can be a challenge in food design – and you’ve probably seen it before: a water-soluble color bleeds into another part of the food.

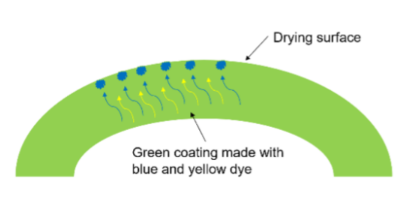

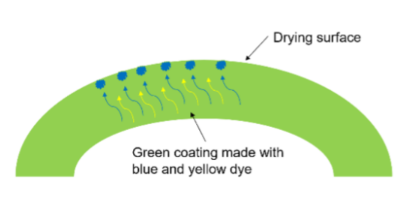

Dyes are more susceptible to migration, while lake pigments are not. One common cause of color migration is uneven distribution of moisture. In this example a green color has been obtained using a mixture of blue and yellow soluble dyes. The blue dye tends to migrate faster than the yellow dye and may accumulate at the surface of the coating, resulting in bluish spots or patches.

In general, lakes are typically chosen for higher-moisture products. They are also used in dry mixes or if there is not enough moisture present to dissolve a dye.

Drying

Soluble dyes are very intense color-wise, which is why they are used at very low levels in a coating. Lakes are used at higher levels and contribute to coating suspension solids without a significant increase in viscosity. A lake-based high solids/low viscosity coating system promotes faster drying (there’s less to evaporate), contributing to quicker coating process times.

Ease of Use for Manufacturers

Lake pigments are used in higher concentrations than dyes (0.1-0.3%, versus 0.01-0.03% for dyes). This translates into more forgiving processes with wider margins of error. In manufacturing, this means more allowable variability for operator-to-operator differences, while still maintaining color consistency. With dyes, there is very little margin of error during formulation and manufacturing, and they do tend to lead to an overall increase in process time.

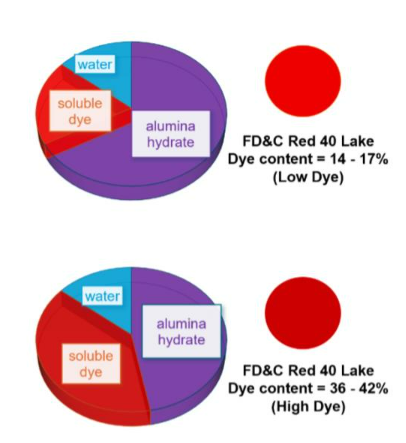

Lakes: Impact of Dye Strength on Color

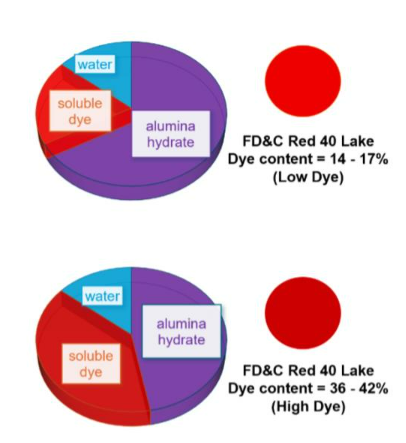

Another important thing to understand is that it is common to source lake pigments in low or high dye strengths. Higher dye strengths indicate a stronger color (see FD&C Red 40 example, right). The dye strength can also range across different shades. For example, low dye Red 40 is more yellow, while high dye Red 40 is more blue.

Another important thing to understand is that it is common to source lake pigments in low or high dye strengths. Higher dye strengths indicate a stronger color (see FD&C Red 40 example, right). The dye strength can also range across different shades. For example, low dye Red 40 is more yellow, while high dye Red 40 is more blue.

Learn More From Colorcon, the Expert on Lakes

Colorcon is one of only a handful of companies that produce FDA-certified lake pigments nationally for use in food and drugs. Applications for our pigments range from cosmetics and pharmaceuticals to chewing gum, candy and more. They can offer a number of advantages over dyes, including opacity, migration, drying, and ease of use. Lakes can help achieve colors in products where dyes are not compatible or feasible.

If you would like to learn more about our FD&C lakes and dyes or learn which option would be best for your next food or confectionery project, give us a call!

Mike Gilbert is the General Manager of Specialty Markets at Colorcon and will celebrate 25 years with the company in August of 2023. Mike has held many leadership positions with Colorcon, both technical and commercial, focusing helping customers achieve their goals project by project. In his work, color has always been a critical component for helping achieve product differentiation and enhancing customer appeal.

Mike Gilbert is the General Manager of Specialty Markets at Colorcon and will celebrate 25 years with the company in August of 2023. Mike has held many leadership positions with Colorcon, both technical and commercial, focusing helping customers achieve their goals project by project. In his work, color has always been a critical component for helping achieve product differentiation and enhancing customer appeal.

stability.

stability. ability to deliver a more uniform appearance at lower weight gains.

ability to deliver a more uniform appearance at lower weight gains.

Another important thing to understand is that it is common to source lake pigments in low or high dye strengths. Higher dye strengths indicate a stronger color (see FD&C Red 40 example, right). The dye strength can also range across different shades. For example, low dye Red 40 is more yellow, while high dye Red 40 is more blue.

Another important thing to understand is that it is common to source lake pigments in low or high dye strengths. Higher dye strengths indicate a stronger color (see FD&C Red 40 example, right). The dye strength can also range across different shades. For example, low dye Red 40 is more yellow, while high dye Red 40 is more blue. Mike Gilbert is the General Manager of Specialty Markets at Colorcon and will celebrate 25 years with the company in August of 2023. Mike has held many leadership positions with Colorcon, both technical and commercial, focusing helping customers achieve their goals project by project. In his work, color has always been a critical component for helping achieve product differentiation and enhancing customer appeal.

Mike Gilbert is the General Manager of Specialty Markets at Colorcon and will celebrate 25 years with the company in August of 2023. Mike has held many leadership positions with Colorcon, both technical and commercial, focusing helping customers achieve their goals project by project. In his work, color has always been a critical component for helping achieve product differentiation and enhancing customer appeal.