The internet is full of stories (and pictures) of discolored foods. A packaging printing error is one thing, but what if you unwrapped a dark chocolate bar and found it was…grey?

Inconsistent color can be a major issue in your food manufacturing operation. It’s something consumers tend to be very vocal about, often sharing on social media platforms. And that - right there - can snowball into a food company’s worst nightmare.

While food and confectionery manufacturers often can’t prevent an unscrupulous vendor from selling older candy bars on their shelves, they can control color consistency at the point of manufacture to ensure product uniformity and avoid unnecessary consumer dismay due to production errors.

Color consistency plays a leading role.

Choosing the Right Color Vendor is Essential

Choosing the Right Color Vendor is Essential

The Turn Bar blog post discusses key ink traits that are relevant not only to packaging, but to food and confectionery food manufacturing. They pointed out that color standards are a critically important practice to ensure products match a targeted color since “perfection is the only option.”

Even in spite of best efforts, color variability can present a problem. For this reason, a clear understanding of ingredient quality and how best to achieve accurate color representation is vital.

It all starts with vendor selection.

Over the years, brands that have placed color consistency on the back burner have often seen their product lines take a hit, some of which have even been abandoned by consumers.

Precise color representation is challenging, given the need for accurate reproduction on a variety of food surfaces (think: chocolate, peanut butter or licorice), which will be applied with varying types of equipment, operated by a wide range of people, using different techniques, in all manner of production environments.

Variability inevitably occurs, which can result in product flaws leading to a loss of consumer confidence in the brand.

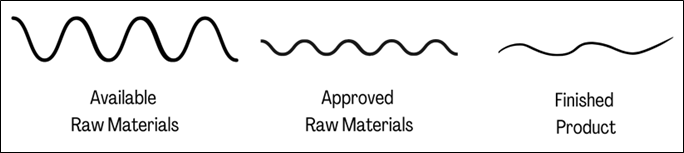

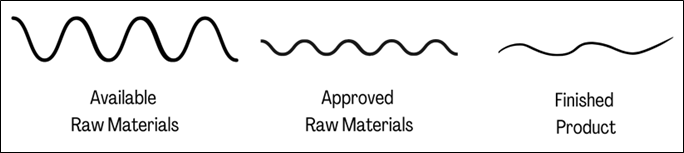

Minimizing color variability starts before batch manufacturing even begins. Proactive brands do this by ensuring the highest degree of raw material consistency possible and establishing standards at the start of the manufacturing cycle to help flatten the wave of variability throughout the process and in the finished product.

Here are two recommendations food and confectionery manufacturers should implement (if they haven’t already) to ensure supplier quality.

- Use a meticulous raw material risk assessment and supplier approval process to achieve batch-to-batch consistency.

Effective supplier approval and management can help maintain lot-to-lot consistency of raw materials, lowering the risk of batch-to-batch color variability.

Qualification of raw material suppliers is a must and should include a consistent record of acceptable product quality. Look at the number of years in business, customer opinions, past audit results and – critically – adherence to all industry standards and relevant regulatory requirements. As the Colorcon No-Tox team pointed out, we require robust vendor screening, and product grade selection to find the right match for customer applications.

- Employ a dedicated material review team to ensure quality.

A material review team should consist of representation from all 3 elements of the product-quality system. The Colorcon No-Tox post describes these 3 quality stakeholders:

- Regulatory Affairs confirms that materials are acceptable for use within the applications and intended distribution markets. This team must keep current with the ever-changing regulations by region and ensure individual materials meet the required guidelines.

- Quality Assurance (QA) maintains compliance and oversees process controls. The QA team confirms individual suppliers meet standards, provides supplier monitoring and oversight, as well as maintains a high level of supplier dependability.

- Quality Control (QC) must control product specification adherence and ensure consistency from batch to batch. It’s QC’s responsibility to ensure raw materials meet specifications that align with customer needs.

Techniques for Maintaining Consistent, High-Quality Color

Whether color matching paints or hard panning a well-known candy, the use of color comparison testing to ensure quality has been a staple of decorators and color suppliers alike for decades. Unfortunately, reproducibility has been a struggle for just as long. During raw material selection, color comparison testing of the components in a final colorant product help manufacturers set standards and create reproduceable commercial-scale formulations.

Color consistency is highly dependent on color measurement. Two key color measurements within our industry are:

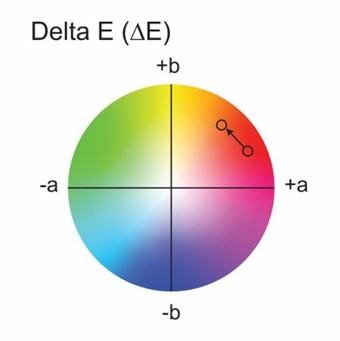

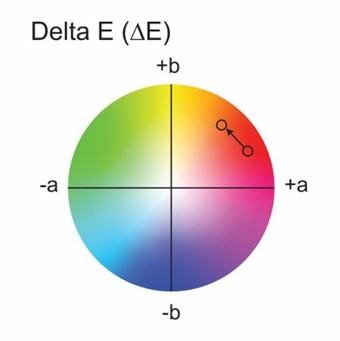

Delta E measures color differences between samples and known quality standards. These measurements allow us to create more consistent colorants from batch to batch. “Delta” is a mathematical term referencing the change in a variable or function, while the suffix “E” references the German word empfindung, meaning “sensation.” Thus, Delta E translates to “a difference in sensation.” Laboratory equipment utilizing Delta E Values are designed to identify deviations when comparing colorants to known values. These deviations allow for refinements before and during the manufacturing process, which in turn, creates a more consistent and reliable product.

L*a*b* is more detailed look at color consistency, but also a little bit more difficult to describe. Think about it as geographic coordinates such as longitude, latitude and altitude. In this case, ‘L’ refers to lightness, ‘a’ is a value on the red/green axis, and ‘b’ is a value on the blue/yellow axis. These values provide a way to find and describe colors. L*a*b* allows for a stronger evaluation of colorant measurements, allowing for fine-tuning during the manufacturing process. This in turn, leads to colorant products that meet even the strictest of color standards.

Quality control departments use a range of tools and equipment to analyze this data to ensure manufacturing of the product meets customer specifications and expectations. Technologies have improved, as has the industry’s ability to manage and measure color properly, which translates to greater peace-of-mind for customers and consumers. While such advances in instrumentation and expertise have dramatically reduced inconsistencies in the use of color in food production, there are steps manufacturers can take to maintain color consistency from batch-to-batch.

‘Color variability’ is synonymous with ‘quality variability’ – and it’s a bad look (literally) for any food or confectionery brand.. Partnering with an experienced manufacturer with robust quality systems and color expertise can help accelerate project timelines, improve yields, reduce the total cost to manufacture and protect brand reputation.

Since 2017, Daniel Zogg has served in multiple Quality Assurance and Regulatory Affairs Management positions for Colorcon’s West Point and Chalfont locations. Daniel manages Colorcon processes aimed at optimizing product realization, improving customer interfacing, and streamlining Quality Management Systems. Daniel, a graduate of the University of Delaware, has numerous industry certifications.

Since 2017, Daniel Zogg has served in multiple Quality Assurance and Regulatory Affairs Management positions for Colorcon’s West Point and Chalfont locations. Daniel manages Colorcon processes aimed at optimizing product realization, improving customer interfacing, and streamlining Quality Management Systems. Daniel, a graduate of the University of Delaware, has numerous industry certifications.

Choosing the Right Color Vendor is Essential

Choosing the Right Color Vendor is Essential

Since 2017, Daniel Zogg has served in multiple Quality Assurance and Regulatory Affairs Management positions for Colorcon’s West Point and Chalfont locations. Daniel manages Colorcon processes aimed at optimizing product realization, improving customer interfacing, and streamlining Quality Management Systems. Daniel, a graduate of the University of Delaware, has numerous industry certifications.

Since 2017, Daniel Zogg has served in multiple Quality Assurance and Regulatory Affairs Management positions for Colorcon’s West Point and Chalfont locations. Daniel manages Colorcon processes aimed at optimizing product realization, improving customer interfacing, and streamlining Quality Management Systems. Daniel, a graduate of the University of Delaware, has numerous industry certifications.